We will explore the top-rated Breitling replica watches that offer an authentic look, precision, and exclusivity.

Our replica watches are molded 1:1 to the original factory and every part and detail matches the original.

Buy authentic Replica Cartier Fake watches. Cartier watches collection for ladies & mens.

<

Organization is fundamental to any type of warehouse cleaning plan. If your warehouse is not organized, the inventory may get lost or misplaced, which can get in the way of your cleaning processes. An easy way to stay organized is by using racks and shelves in your warehouse facilities. These fixtures will ensure every inch of your warehouse space is utilized efficiently. Plus, your workers can easily locate and access the goods when everything is organized in racks and shelves.

Step #2: Organize the warehouse space with labels.

After organizing your merchandise in racks and shelves, you need a labelling system that clearly indicates the location of various products. Once the merchandise is brought in, clearly mark the containers to identify the goods and indicate their assigned positions in the warehouse. If you are using a forklift to move goods over short distances in the warehouse, use pallet positions to avoid the stock from being dumped in the wrong place. Also, set apart specific parking spaces for your forklifts when they are not in use.

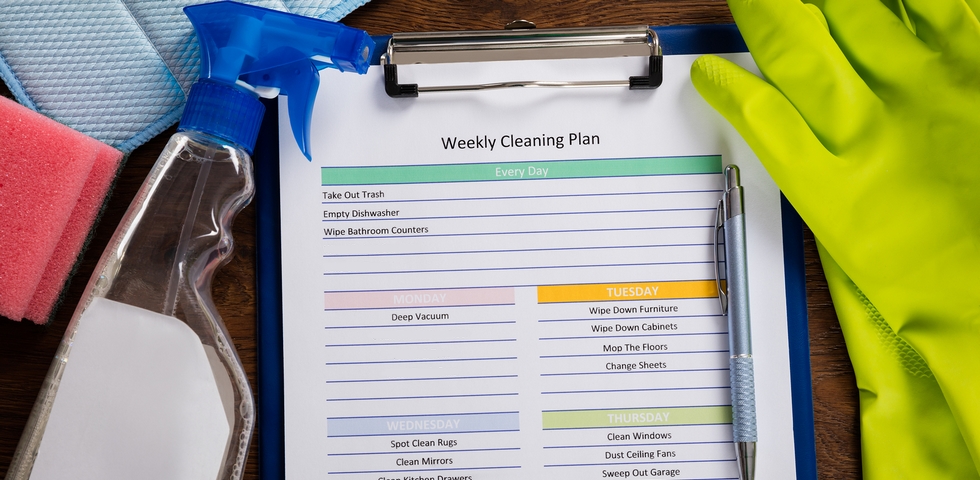

Step #3: Outline your warehouse cleaning plan.

As mentioned earlier, you need to establish a thorough warehouse cleaning plan. This includes an outline of which areas need to be cleaned and how often it should occur. For instance, you could prioritize areas with the most traffic, such as the docking area where merchandise is loaded or offloaded. Depending on the available resources, these areas could be cleaned daily, weekly, or even monthly.

Once you identified the areas in your warehouse that require cleaning, come up with a schedule and establish a regular time for the cleaning process to take place. This schedule is helpful so that your warehouse workers and the professional cleaners won’t disrupt each other’s work.

Step #4: Place plenty of waste bins around the warehouse.

You will be amazed with how much waste is generated in a warehouse, even when you are an eco-friendly business. With warehousing comes waste from cardboard boxes, papers, bubble wrappers and other materials that should be disposed of appropriately. Otherwise, your warehouse could become cluttered with heaps of packing materials piling up after just a few days.

As part of your warehouse cleaning plan, you should place garbage bins at strategic points throughout the warehouse. The garbage bins should be placed preferably after every 40 feet, or an even shorter distance if possible. Providing waste bins will encourage employees to keep the working environment tidy and not litter around the premises. Remember to empty these garbage bins as soon as they are nearly full.

Step #5: Start recycling in your warehouse.

Warehouses may generate a lot of waste, but you can reduce the waste materials by implementing an effective recycling initiative. The key objectives to your warehouse cleaning plan should be reduce, reuse, and recycle. First, reduce any unnecessary waste in your business operations and processes. Then, reuse these materials instead of disposing them. Finally, recycle whatever is available. These recyclable items include wood, paper, metal, steel, iron and glass unless they are damaged.

Step #6: Allocate cleaning zones to employees.

Engaging employees in the everyday operations of a business motivates them to work harder at their job. This is because they know they are making a significant contribution to the overall productivity and success of the organization. For this reason, each employee should be assigned a specific section of the warehouse. This employee should be held accountable for making sure the space is clean and presentable.

As their manager, you can declare that employees may only leave work once their assigned cleaning area has been inspected and found to meet the organization’s standards of cleanliness. The employees could pick up garbage left on the floor, dust the racks and shelves, or wash the floors with the recommended cleaning detergents and equipment.

Make sure the cleaning equipment is easily accessible to your staff. The employees shouldn’t have to cross over to the other end of the warehouse just to retrieve a mop or other cleaning supplies. On days when there isn’t much activity in the warehouse, ask the employees to clean their assigned zones thoroughly. They could even work in teams to get the work done much faster.